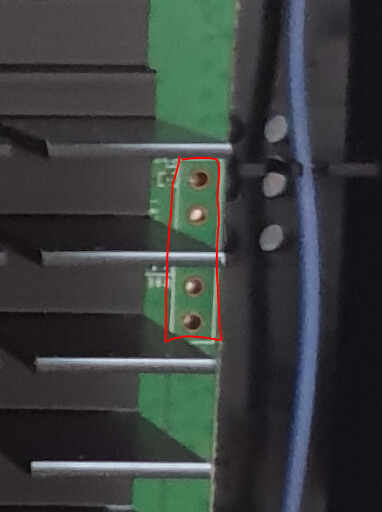

I've been soldering for 40+ years and specialise in rework, so maybe I can chime in about the way I'd approach this.

First, the material in the holes will be lead-free solder, applied during the manufacturing process, as others have said.

Second, lead-free has a melting points higher than leaded solder, which nowadays is normally used only for re-work/repair purposes (there are a few exceptions).

Users often struggle with this kind of situation, but there is an easy option I use all the time:-

Method one - pre-soaking with a hairdryer

preheat the board to raise it above room temperature with a hair dryer. You will find it much easier if you can soak the board in warm air from the hairdryer for a few minutes to get it to around 60-70 degress C. Your normal iron, set to a normal temperature, will have an easier time melting the lead-free solder. This is important because without preheating, you'd be forced to turn the iron heat up so high that you'd damage the board very rapidly. The actual board temperature you need to achive is not critical, but dont go too hot, make sure it is not too hot to handle with your fingertips for example. Just make sure you warm it for a few minutes to enable all layers of copper inside the PCB to rise nicely above room temperature. This can take some time especially around areas that have a lot of ground or power planes (edit: wide expanses of sheet copper, as opposed to narrow traces)

Note: in theory, using such a hairdryer is questionable from a ESD perspective (fast moving dry air creates static discharges), so you can reduce the risk by using a hairdryer on low airflow setting, and not allowing the hairdryer to touch the board or plastic case of the router. If you are very worried, or working on expensive equipment, use proper ESD bonding techniques

ESD edit: the hair dryer is likely to be double-insulated and not easy to ESD bond. Also, on static discharges, proper ESD reduction techniques advocate slow discharge through a high-value resistor not just for human safety, it's to reduce the charge flow to non-damaging levels. So "earthing yourself by touching something metal" isn't really the best thing to do, especially if you have already built up a few thousand volts in your body (not unusual in a domestic environment)

But hey - for a 5euro commodity CPE/ISP router I don't bother. But for a 300 Euro special or commercial work, I bond everything properly.

Always use corded wrist straps, not scam cordless ones.

Method two:

Low-melting point 58% Bismuth solder for initial cleanout.

The other technique I use, when the hairdyer heat soak fails, is to try to remove some of the solder by using bisthmuth paste low-melting point solder to repeatedly wick out the lead-free solder. It is avilable in small pots for BGA rework jobs. You will never reach a true eutectic mix of the two solders, but an ad-hoc mix of Bi-58 with high-melting-point lead-free usually allows some more of the lead-free to be removed with each attempt, and so gradually the hole can be cleared. If you can't get 58% bisthmuth (Bi) solder paste, then you could try to persist wih 63/37% lead/tin solder, which has a very slightly lower meting point (only a few degrees) lower than the more usual 60/40 lead/tin solder but crucially has a wider eutic range so is very slightly easier to work with.

I don't use Wood's Metal,

NOTE: Bismuth solders are NOT usually suitable for permanent use as they can develop some mechanical problems over time where there is any movement or there is no conformal coating or solder mask/laquer. Clean up well with liquid flux (edit: with desolder wick) and use lead/tin solder for the actual soldering later.

HOWEVER: for one-off attachment of TTL-serial you can often temporarily attach the very thin flexible wires (GND, TX and RX to the board with a blob hot glue nearby then temporarily solder then to the respective pads using Bisthuth solder paste alone. edit: use very thin flexible wires around 32SWG/30AWG or finer, also prebend the ends by nipping with blunt/polished tweezers so they lie correctly with no tension - or warm gently with an nearby warm soldering iron to soften the insulation more into shape) This is temporary and not suitable for lontgerm situations but for example when doing the inital flash of a router to change from OEM to OpenWRT (BT Homehub 5A comes to mind) it is worth a try and is far faster than fitting pins. you are relying on the solder mask to provide some insulation from the ground plane so talke it easy with the iron. Strip a mm or two of the wire ends - that's all. Tin the pads first with a tiny amount of Bismuth paste, then tin the wires too. Then hold the stripped, tinned with end down on the pad

with a flat screwdriver tip and apply the iron for a slit second. Hold the screwdriver very still for the next 10 seconds, then see if you have a good joint.

For expensive or troublesome rework like this I both preheat AND use Bismuth paste.

related tips: use a LARGE iron tip (NOT small or too fine). A large tip has high thermal mass so it does not cool rapidly when it hits the board. This avoids the need to crank up the iron temperature way too high, a common mistake.

It must also be clean and tinned (I use salmiak for tip cleaning, also a genione brass swarf "pad scrub" ball). I mainly use rosin flux in alcohol to make a liquid flux, but clean flux residue carefully with Isopropyl alcohol (or rubbing alcohol) to avoid future problems.

Always have good ventilation, but avoid draughts on your work as rapid cooling leads to bad joints.

Rosin/colophony and salmiac have vapour hazards, can trigger alergies and cause occupational asthma. Lead has serious longterm health effects etc etc